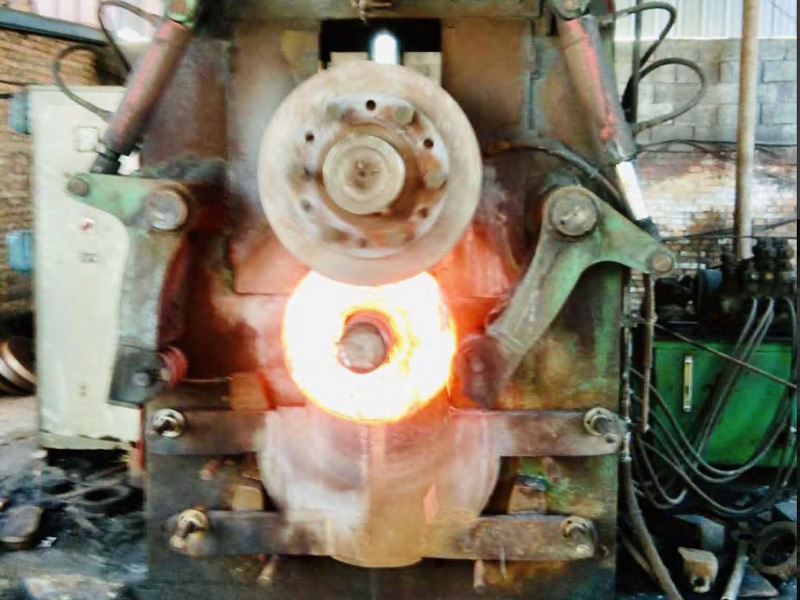

What are the causes of defects in stainless steel forgings?

The superior quality of raw materials is a prerequisite for ensuring the quality of forgings. If the raw materials have defects, it may affect the forming process and quality of the forgings. If the chemical composition of the raw materials exceeds the specified range or the content of residual elements is too high, it will have a significant impact on the forming and quality of forgings. For example, S, B, Cu, Sn, etc., are classic elements that easily produce low-melting-point phases, making stainless steel forgings prone to hot brittleness. In order to obtain fine-grained steel, the residual aluminum content in the steel needs to be controlled within a certain range. If the aluminum content is too low, it will not play a role in controlling the grain size, and the actual grain size of the forgings is likely to be unqualified. If the aluminum content is too high, during pressure processing under conditions that produce fibrous structures, it is easy to produce wood-grain-like fracture surfaces, tear-like fracture surfaces, etc.

Jan 10,2022

Pre-treatment of stainless steel forgings

Preprocessing is a crucial process before stainless steel forgings undergo surface treatment (including pickling and passivation, electropolishing and electrochemical polishing, electroplating, passivation, blackening, coloring, chemical processing, etc.). During the processing of stainless steel forgings, the surface may be stained with oil, burrs, uneven surfaces, and metal oxides. Therefore, before surface treatment, it is essential to remove oil stains, burrs, uneven surfaces, and metal oxides to ensure satisfactory results in subsequent processing.

Nov 12,2021

More information