Pre-treatment of stainless steel forgings

Release time:

Nov 12,2021

Preprocessing is a crucial process before stainless steel forgings undergo surface treatment (including pickling and passivation, electropolishing and electrochemical polishing, electroplating, passivation, blackening, coloring, chemical processing, etc.). During the processing of stainless steel forgings, the surface may be stained with oil, burrs, uneven surfaces, and metal oxides. Therefore, before surface treatment, it is essential to remove oil stains, burrs, uneven surfaces, and metal oxides to ensure satisfactory results in subsequent processing.

1. Importance of Preprocessing

Preprocessing is a crucial process before surface treatment (including pickling passivation, electropolishing and electrochemical polishing, electroplating, passivation, blackening, coloring, chemical processing, etc.) of stainless steel forgings. During the processing of stainless steel forgings, the surface may be contaminated with oil stains, burrs, uneven surfaces, and metal oxides. Therefore, before surface treatment, it is essential to remove oil stains, burrs, uneven surfaces, and metal oxides to ensure satisfactory results in subsequent processing.

2. Waste to be Removed During Processing

Waste to be removed from the surface of stainless steel during pretreatment can be divided into two categories: organic compounds and inorganic compounds.

(1) Organic waste: This type of oil stain mainly comes from lubricating oil, cutting fluid, quenching fluid, polishing paste and polishing wax, and fingerprints used in the processing of stainless steel parts.

(2) Inorganic waste: Includes soil, dust particles, metal oxides generated during heat treatment, etc.

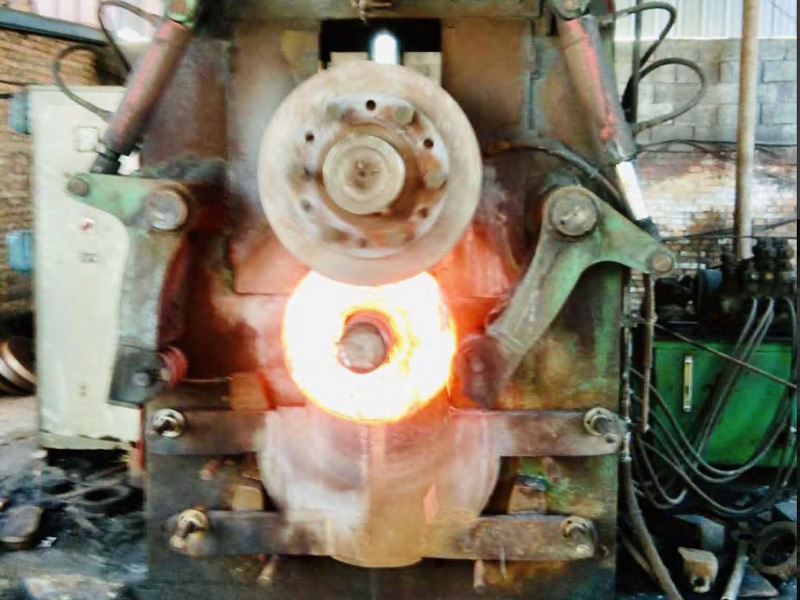

What should be noted in the production process of flange forgings?

The forming method of flange forgings is determined based on the diversity of the forging geometry and the processing accuracy and symmetry of the forgings. At the same time, considering that the forming problem of this gear forging is the convex block part at the upper and lower ports, and its deformation degree reaches more than 809/6, in order to ensure the forming of each convex block, it is determined to use closed isostatic pressing for warm forging. The mold guidance is set by using the positioning pin and the guide column diagonal line method to avoid exceeding the allowable range of the shape tolerance of the upper and lower convex blocks due to the displacement of the convex and concave molds.

In addition, better lubrication is needed to further ensure successful demolding, reduce mold damage, and ensure the feasibility and reliability of the process. From the analysis of the forging drawing, in order to ensure the rationality and processing accuracy of the gear forging forming, as well as the stable operation of the mold, the upper port with a diameter of 42 mm can be used as the parting surface, that is, the three convex blocks at the upper port are isostatically pressed in the mold seat, and the cylindrical step and the four convex blocks at the lower port are formed in the cavity.

The materials used for forging flange forgings are usually various carbon steels and carbon steels, followed by aluminum, magnesium, copper, titanium, and aluminum alloys. The original states of the raw materials include round bars, castings, metal powders, and shape memory alloys. The ratio of the cross-sectional area before deformation to the cross-sectional area after deformation of the metal is called the forging ratio. Accurately selecting the forging ratio, reasonable heating temperature and insulation time, reasonable initial forging temperature and final forging temperature, and reasonable deformation amount and deformation rate are very important for improving product quality and controlling costs.

Keywords:

More information