What are the causes of defects in stainless steel forgings?

Release time:

Jan 10,2022

The superior quality of raw materials is a prerequisite for ensuring the quality of forgings. If the raw materials have defects, it may affect the forming process and quality of the forgings. If the chemical composition of the raw materials exceeds the specified range or the content of residual elements is too high, it will have a significant impact on the forming and quality of forgings. For example, S, B, Cu, Sn, etc., are classic elements that easily produce low-melting-point phases, making stainless steel forgings prone to hot brittleness. In order to obtain fine-grained steel, the residual aluminum content in the steel needs to be controlled within a certain range. If the aluminum content is too low, it will not play a role in controlling the grain size, and the actual grain size of the forgings is likely to be unqualified. If the aluminum content is too high, during pressure processing under conditions that produce fibrous structures, it is easy to produce wood-grain-like fracture surfaces, tear-like fracture surfaces, etc.

There are many reasons that affect the quality of stainless steel forgings, mainly the raw materials and the casting process.

I. The impact of raw materials on the quality of stainless steel forgings

The superior quality of raw materials is a prerequisite for ensuring the quality of forgings. If the raw materials have defects, it may affect the forming process and quality of the forgings. For example, if the chemical composition of the raw materials exceeds the specified range or the content of residual elements is too high, it will have a great impact on the forming and quality of the forgings. For example, S, B, Cu, Sn, etc., are classic elements that easily produce low-melting-point phases, making stainless steel forgings prone to hot brittleness. In order to obtain fine-grained steel, the residual aluminum content in the steel needs to be controlled within a certain range. If the aluminum content is too low, it will not play a role in controlling the grain size, and it is easy to cause the actual grain size of the forgings to fail to meet the requirements; if the aluminum content is too high, it is easy to produce a woody texture fracture surface and a tear-like fracture surface under the conditions of fiber tissue formation during pressure processing.

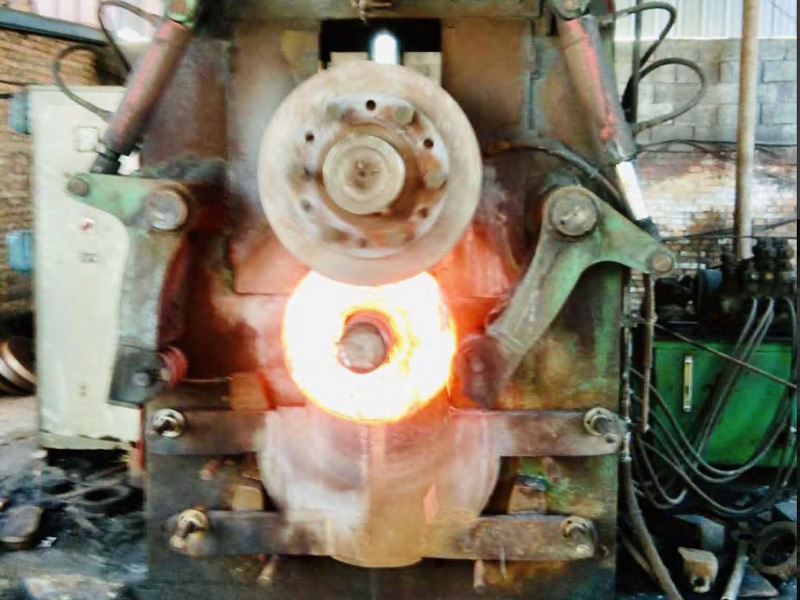

II. The impact of the casting process on the quality of stainless steel forgings

The casting process generally consists of the following processes: blanking, heating, forming, post-forging cooling, pickling and passivation, and post-forging heat treatment. If the process is unreasonable during the forging process, a series of defects in stainless steel forgings may occur. The heating process includes the charging temperature, heating temperature, heating rate, insulation time, and furnace gas composition. If the heating is unreasonable, such as too high heating temperature and too long heating time, it will also cause defects such as carburization, overheating, and coarse crystals. For large cross-section, poor thermal conductivity, and low plasticity billets, if the heating is too fast and the insulation time is too short, the temperature distribution is usually uneven, resulting in internal stress, which causes the billet to crack.

Forging forming technology includes deformation methods, deformation degree, deformation temperature, deformation rate, stress state, die condition, and lubrication requirements. If the forming process is unreasonable, it may cause coarse grains, uneven grains, various cracks, folding, penetration, swirls, residual casting structure, etc. In the post-forging cooling stage, if the process is unreasonable, it may cause cooling cracks, white spots, network carbides, etc.

Keywords:

More information