The difference between steel plate flanges and forged flanges

Release time:

Apr 16,2025

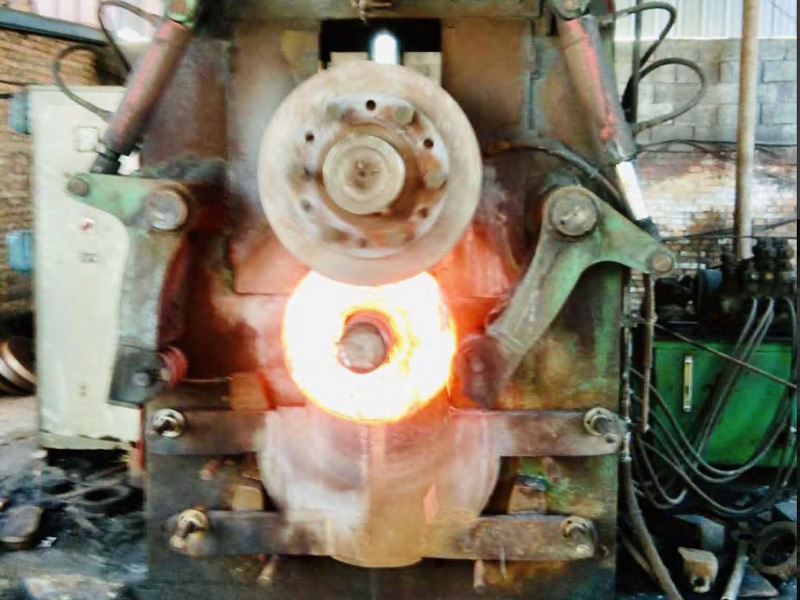

Forged flanges are made from forged blanks and then machined. For the same material, forging increases density, strength, and toughness compared to non-forged flanges. Steel plate flanges are made from steel plate cutting and then machining. Because forging is a high-precision process, forged flanges are more expensive than steel plate flanges. However, the quality of steel plate flanges should not be doubted; they perform well in low-pressure applications, while forged flanges are suitable for high- and medium-pressure applications.

Forged flanges are made from forged blanks, then machined. For the same material, forged flanges have higher density, resulting in improved strength and toughness; steel plate flanges are made by cutting steel plates and then machining them. Because forged flanges represent a higher level of craftsmanship, their cost is higher than steel plate flanges. However, the quality of steel plate flanges should not be underestimated; they are very effective for low-pressure applications, while forged flanges are suitable for medium- and high-pressure applications.

Forged and steel plate flanges have some differences in appearance. Forged flanges are certainly of higher quality, but the choice depends on whether the application is high-pressure, medium-pressure, or low-pressure. Steel plate flanges are sufficient for low-pressure applications.

Many materials can be forged, such as carbon steel, alloy steel, and stainless steel. Forged flanges are suitable for medium- and high-pressure applications, while steel plate flanges are suitable for low-pressure applications.

Keywords:

More information