Precautions for flange installation

Release time:

Apr 16,2025

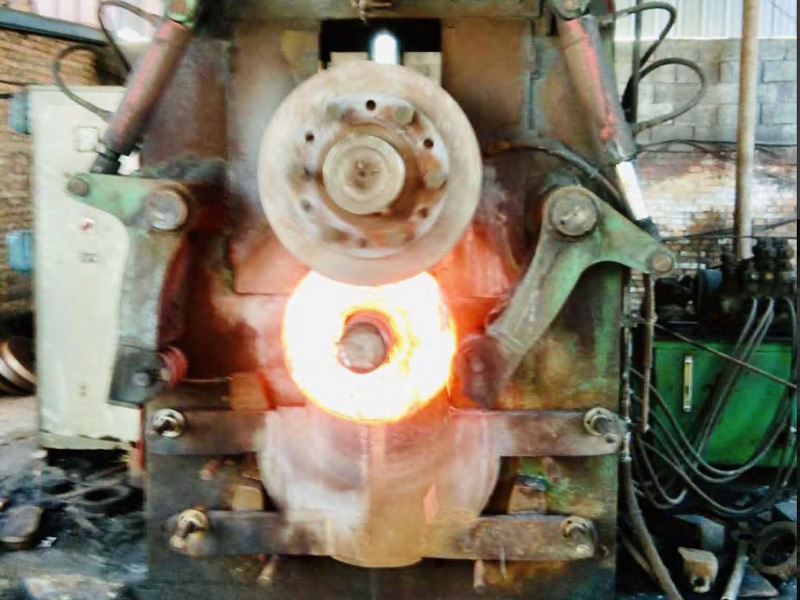

Flanges are mainly used in the connection of equipment and pipelines, bringing much convenience to the connection of equipment and pipelines. There are many details that need our attention when installing and using flanges.

Flanges are primarily used for connecting equipment and pipes, offering great convenience in equipment and pipe connections. When installing and using flanges, there are many details that require our attention:

1. When tightening flanges, the direction should be consistent, and the compression of the gasket should be controlled to about one-third.

2. During installation, the sealing surfaces of the flanges should be kept flat and clean. If oil stains or rust spots are found, they should be cleaned to prevent affecting the sealing performance of the flange.

Flanges are commonly used fittings in pipe equipment. They connect pipelines and equipment together with pipe fittings such as elbows, tees, and valves. During pipe use, due to different media, temperatures, and flow rates of the transported materials, different pipe lengths, horizontal heights, and pressures generated by concrete pump power, special attention should be paid to the material and quality of pipe components and fittings when selecting them. When purchasing pipes and fittings, carefully check against national and international standards, conduct sufficient design and evaluation of the required product dimensions and pressure, carefully select carbon steel fittings, alloy steel fittings, stainless steel fittings, and other material fittings as needed, and strictly control the quality and technical requirements, production, and testing processes of the fittings.

Flange materials can be divided into: carbon steel Q235.20#, stainless steel 304.316.304L.316L.S321.S310, duplex steel 31803.S2025, alloy steel 16Mn, 12CrMo, and many other types, which can be selected as needed; implementation standards include GB/T9119, HG/T20592, and American, German, and Japanese standards, etc.

There are many types of flanges, including plate flat welding flanges, weld neck flanges, weld neck butt welding flanges, socket welding flanges, threaded flanges, flange covers, butt welding loose flanges, flat welding loose flanges, ring groove surface flanges and flange covers, large-diameter flat flanges, large-diameter high-neck flanges, blind flange, etc. Models and sizes range from nominal diameter DN10 to DN4000+; shapes can be round, square, oval, and various irregular shapes.

In the procurement, sales, and use processes, pipe fittings should be selected according to their purpose. It is recommended to abide by design principles, use national standard pipe fittings, and select general standard series flanges. Considering that non-standard and secondary standard flanges are selected in practical applications, please use them cautiously and pay attention to engineering quality and safety! While considering construction and operation costs, strive for a double harvest of safe production and economic benefits.

Keywords:

More information