Analysis of application scenarios of stainless steel flanges in Sinopec

Release time:

Jul 28,2022

Introduction: In the petrochemical industry, the safety and reliability of pipeline connections are crucial. Stainless steel flanges, as an important type of pipeline connector, are widely used in large petrochemical enterprises such as Sinopec due to their excellent corrosion resistance and stable mechanical properties. This article will provide a detailed analysis of the application scenarios of stainless steel flanges in Sinopec, in order to provide reference and guidance for engineering and technical personnel in this field.

I. Introduction In the petrochemical industry, the safety and reliability of pipeline connections are crucial. Stainless steel flanges, as an important type of pipeline connector, are widely used in large petrochemical enterprises such as Sinopec due to their excellent corrosion resistance and stable mechanical properties. This article will provide a detailed analysis of the application scenarios of stainless steel flanges in Sinopec, hoping to provide reference and guidance for engineering and technical personnel in this field.

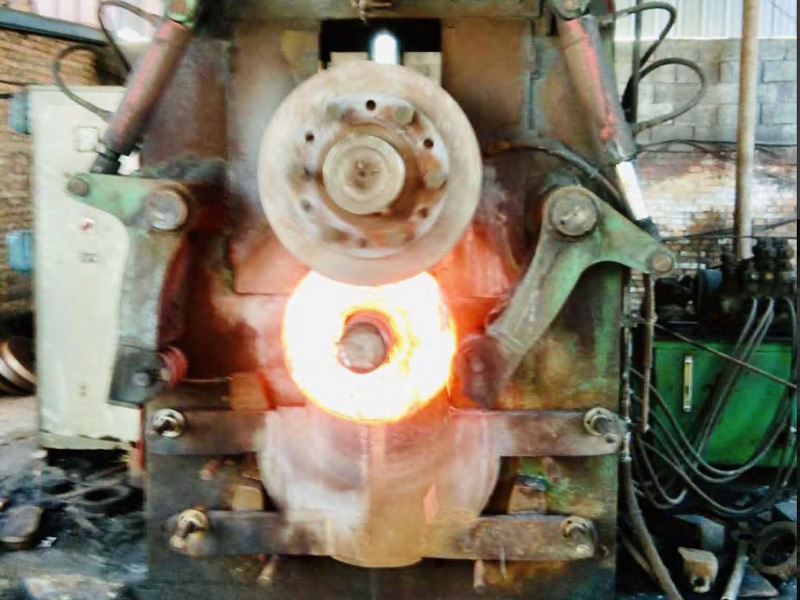

II. Basic Characteristics of Stainless Steel Flanges Stainless steel flanges, usually made of stainless steel materials, have excellent corrosion resistance, high temperature resistance, and mechanical strength. These characteristics make stainless steel flanges widely used in many industries such as petrochemicals, pharmaceuticals, and food. They are especially indispensable in petrochemical enterprises such as Sinopec.

III. Main Application Scenarios of Stainless Steel Flanges in Sinopec 1. Crude Oil and Natural Gas Transmission Pipelines In Sinopec's crude oil and natural gas transmission pipeline systems, stainless steel flanges are widely used in pipeline connection and sealing. Because crude oil and natural gas contain a large number of corrosive media, such as hydrogen sulfide and carbon dioxide, stainless steel flanges with excellent corrosion resistance are needed to ensure the safe operation of the pipelines. In addition, the high strength and high sealing performance of stainless steel flanges can effectively prevent pipeline leakage and safety accidents.

2. Chemical Equipment Connections In the chemical production process, various chemical equipment needs to be connected through pipelines. Stainless steel flanges, as pipeline connectors, play an important role in chemical equipment connections. Because chemical equipment often contains corrosive media such as strong acids and strong alkalis, stainless steel flanges with good corrosion resistance are needed to ensure the reliability and safety of equipment connections.

3. High-Temperature and High-Pressure Pipeline Systems In the petrochemical industry, high-temperature and high-pressure pipeline systems are common process equipment. These pipeline systems have high requirements for the high-temperature and pressure resistance of connectors. Stainless steel flanges, with their excellent high-temperature resistance and mechanical strength, are the ideal choice of connectors for high-temperature and high-pressure pipeline systems. Stainless steel flanges can withstand thermal and mechanical stresses under high-temperature and high-pressure environments, ensuring the stable operation of the pipeline system.

4. Environmental Protection Facilities With the increasing awareness of environmental protection, petrochemical enterprises such as Sinopec are paying more and more attention to the construction of environmental protection facilities. In environmental protection facilities, stainless steel flanges also play an important role. For example, in wastewater treatment systems, stainless steel flanges are used to connect various wastewater treatment equipment and pipelines to ensure the smooth progress of the wastewater treatment process. At the same time, due to their excellent corrosion resistance, stainless steel flanges can effectively resist corrosive media in wastewater, extending the service life of the equipment.

IV. Advantages of Using Stainless Steel Flanges in Sinopec Using stainless steel flanges as pipeline connectors in large petrochemical enterprises such as Sinopec has the following advantages: 1. Excellent corrosion resistance, capable of adapting to various corrosive media environments;

2. High strength and high sealing performance, which can effectively prevent pipeline leakage and safety accidents;

3. Strong high-temperature and pressure resistance, capable of meeting the working requirements in high-temperature and high-pressure environments;

4. Good environmental performance, in line with the environmental requirements of modern enterprises.

V. Conclusion Stainless steel flanges have a wide range of applications in petrochemical enterprises such as Sinopec. Their excellent corrosion resistance, high strength, and high sealing performance make them the ideal choice for pipeline connectors. In the future, with the continuous development of the petrochemical industry, the application prospects of stainless steel flanges will be even broader.

Keywords:

More information